|

Overall |

|

|

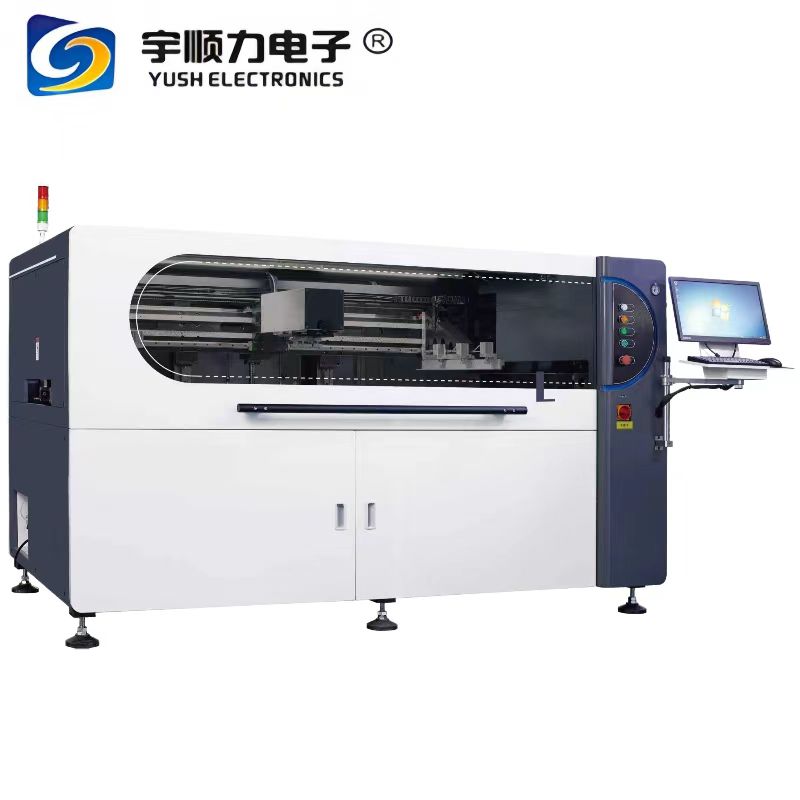

Dimensions(W*D*H) |

1220mm*1450mm*1420mm |

|

Weight |

550KG |

|

Height offset |

60~110mm |

|

Manipulator |

|

|

Motor type |

JiaBao series |

|

Positioning repeatability |

0.001mm |

|

Axis working area(max) |

680mm*360mm*50mm |

|

Work station |

|

|

PCB fixation |

standard,specialization |

|

PCB loading/unloading |

manual |

|

PCB size (max) |

322mm*322mm |

|

PCB thick (max) |

5mm |

|

Fixturing |

|

|

Rigidity fixturing |

standard |

|

Fixturing fixation |

machinery |

|

Spindle Motor |

|

|

Power |

400W |

|

Spindle |

50000rpm/min |

|

Protect |

self/wind cooling |

|

Change cutter |

Specialization |

|

Routing capability |

|

|

Cutting speed(max.) |

100mm/s |

|

Driving speed(max.) |

3000mm/s |

|

Precision of cutting |

0.01mm |

|

Vacuum System |

|

|

Vacuum power |

2.2KW AC 380V |

|

Vacuum |

plumb |

|

Utilities |

|

|

Power |

2.2KW AC380V |

|

Air supply |

2~5KG/cm2 |

|

Programming |

|

|

Program edit |

Inline |

|

Function edit |

Line,arc,circula,U-curve |

|

Program storage |

HDD |

|

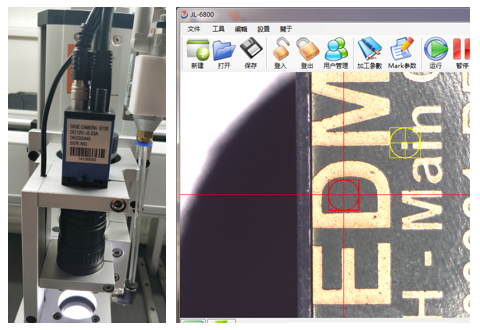

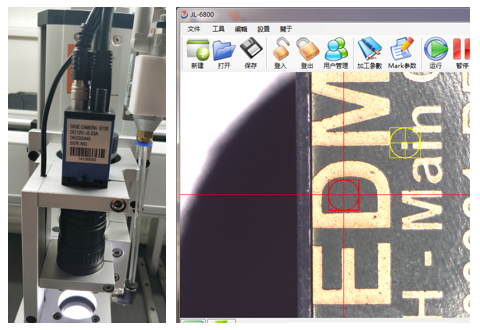

Vision system |

SONE colour CCD |

|

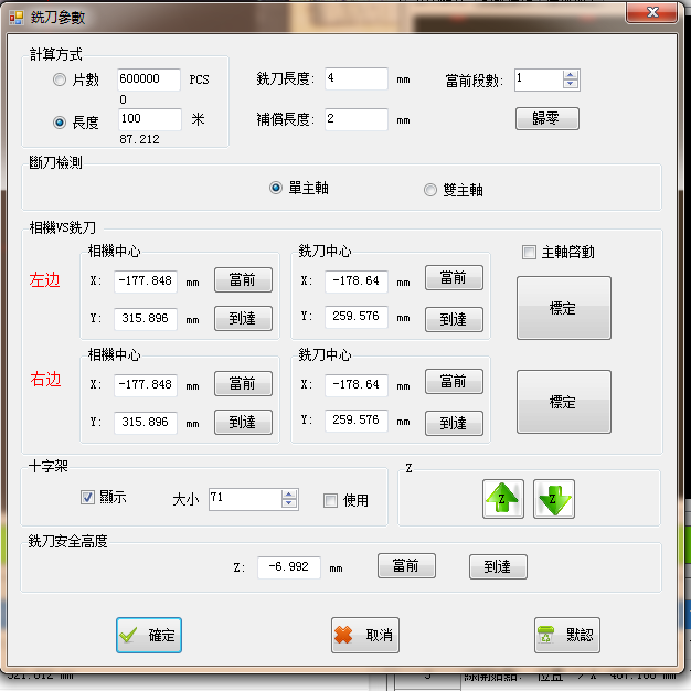

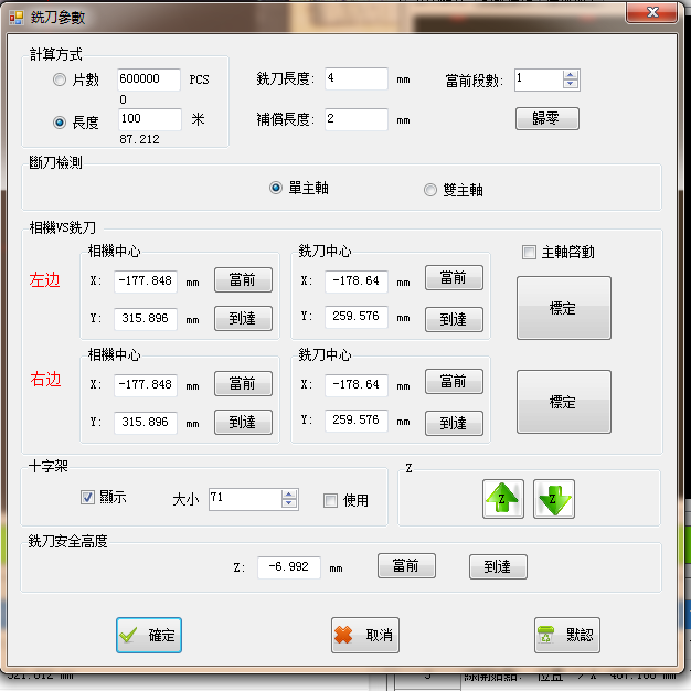

milling cutter offset |

AUTO |

|

Vacuum setup |

AUTO |

|

Operation Monitors |

|

|

Iindicator |

Iindicator Machine state |

|

tool check |

Automatic detection tool life, the use of time testing |

|

Motor protect |

Have overheating, overload, low voltage protection function |

|

motor over loading check |

Have Overload, the line is normal, low voltage protection function |

|

Tool usable time |

Automatic detection tool life, |

|

Data statistic |

Separate board model, separating count, diverse counting methods |

|

Error record |

Software automatically records all alarms memory of machines |

|

III. Accuracy |

|

|

Axis precision |

0.001mm |

|

Cutting precision |

0.1mm |

|

IV. Safety |

|

|

Working area protect |

With four sealed protection |

|

Door sensor |

Front and rear safety door micro-switch sensor (optional) |

|

Exigency stop button |

|

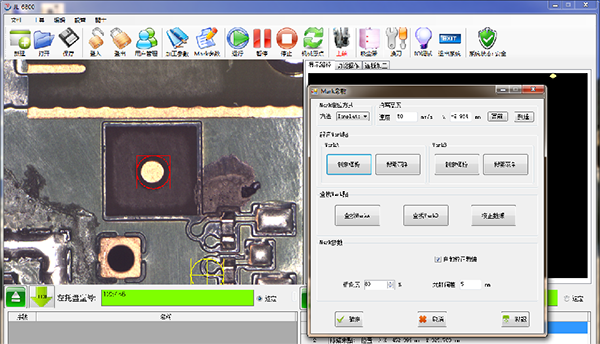

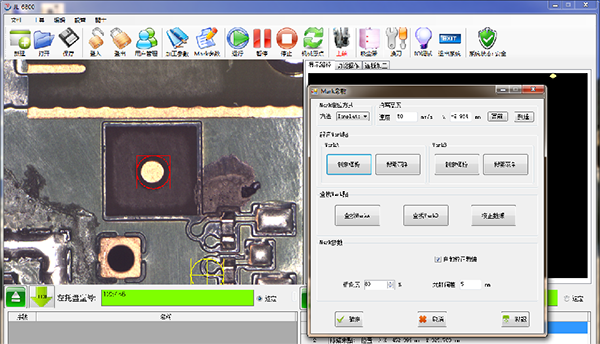

3.Function Description

1.X10 zoom-in image makes programming easier&increase the accuracy of point setting.

2.Two sliding table provides simultaneously in-and-out movement to reduce the tack time for better productivity.

3.AUTO MARK offset system.CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

4.routng bit automatically lift and shift to next programmed point then cutting to extend the life time of routing bit.

5. safety door industry design.

6. CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

PCB ROUTER铣刀分板机机械外观

随着电子工业的不断发展,电子产品重要组成部分基板的生产要求也越来越高,向高精度、高密度、高性能、小体积发展。为了适应市场要求,本公司长期市场调研综合世面上各品牌之优点,广泛听取用户各方面意见,制做出此款高速双模分板机JL-3500。

软件介绍:新一代识别系统

|

1:改变了传统的只能识别圆,方形等几何图型。可以识任何形状标识点。

2:不但具有纠错防呆功能,还可以较准数据,不用担心员工放错板。

3:位移功能,可以实现治具在工作台面任意摆放。 |

|

1:改变了传统的分段模式。

2:根据PCB的厚度来调整下刀深度,增加铣刀利用率,节省成本。

|

结构介绍

采用台湾45000转高速主轴24V高电压静电消除器断刀自动检测功能。采用WIN7系统操作介面,配置高像素彩色CCD放大10倍镜头,辅助程式示教及编辑模拟功能,精度更精确,图像更清晰。

PCB ROUTER铣刀分板机工作结构展示

|

软件介绍: |

双工作台设计 |

电控布局

|

X,Y切割速度 |

0~100mm/s |

|

机器重复精度 |

±0.02 |

|

分板尺寸 |

300mm*350mm |

|

X,Y1,Y2,Z控制方式 |

采用工业运动控制器+工业电脑 |

|

X,Y1,Y2,Z驱动方式 |

禾川伺服电达(可选配日本松下伺服电机) |

|

人机操作及资料储存 |

工业电脑 |

|

切割精度 |

±0.1 |

|

主轴转速 |

台湾主轴Max 45000rpm(可选配日本NSK或德国卡瓦) |

|

切割形式 |

直线、圆形、弧形、U型、L型等 |

|

影像 |

智能工业CCD |

|

操作介面 |

中/英双介面 |

|

Fidicuial Mark |

CCD自动对位功能 |

|

程式预览 |

CCD 路径模拟功能 |

|

主机电压 |

AC 220V 50/60Hz |

|

气压 |

5KG/CM² |

|

主机尺寸 |

1100 x 930 x 1700 (L X H X D)mm |

|

主机重量 |

600kg |

|

集尘方式 |

下集尘(可选下集尘) |

|

集尘器 |

3HP(可选 5HP) |

|

集尘机电源 |

AC 380V 50/60Hz |

|

集尘机尺寸 |

665 x 635 x 1610 (L X H X D)mm |

分板机主要配件

| 丝杆 | 台湾TBI丝杆 |

| 导轨 | 台湾MPI直线导轨 |

| 主轴 | 台湾主轴Max 45000rpm/四方变频器 (可选配日本NSK或德国卡瓦) |

| 伺服电机 | 禾川伺服电达 (可选配日本松下A6伺服电机) |

| 工控主机 | 工业计算机 |

| 显示器 | 飞利浦 LCD17" |

| CCD | 工业智能 CCD |

| 镜头 | 工业高清镜头 |

| 光源 | 工业调光器+50mmLED环型光源 |

| 电源 | 台湾明伟 |

| 继电器 | 欧姆龙继电器组 |

分体选择性波峰焊接机SW-320S全自动 PCB 电路板焊接机 小型锡炉 微型波峰焊机 厂家直销 小型焊接设备 微型波峰焊 小型锡焊机 PCB 焊接设备 迷你波峰焊机 全自动小型锡炉 桌面式波峰焊

桌面式选择性波峰焊ESW-320全自动 PCB 电路板焊接机 小型锡炉 微型波峰焊机 厂家直销 小型焊接设备 微型波峰焊 小型锡焊机 PCB 焊接设备 迷你波峰焊机 全自动小型锡炉 桌面式波峰焊

一体式选择性波峰焊全自动 PCB 电路板焊接机 小型锡炉 微型波峰焊机 厂家直销 小型焊接设备 微型波峰焊 小型锡焊机 PCB 焊接设备 迷你波峰焊机 全自动小型锡炉 桌面式波峰焊

【小型波峰焊 迷你桌上型】全自动 PCB 电路板焊接机 小型锡炉 微型波峰焊机 厂家直销 小型焊接设备 微型波峰焊 小型锡焊机 PCB 焊接设备 迷你波峰焊机 全自动小型锡炉 桌面式波峰焊

干冰清洗机重量50KG模具清洗机PCBA清洗机模塑胶毛刺清洗机波峰焊清洗机汽车发动机清洗金属件油污清轮胎清洗高端电源清洗

桌面型锣板机 PCB锣板机 万能邮票孔锣板机 PCB分板机锣板机 离线式pcb分板机 电路板PCBA锣板机生产厂家 曲线式PCB分板机

干冰清洗机重量50KG模具清洗机PCBA清洗机模塑胶毛刺清洗机波峰焊清洗机汽车发动机清洗金属件油污清轮胎清洗高端电源清洗

|

Overall |

|

|

Dimensions(W*D*H) |

1220mm*1450mm*1420mm |

|

Weight |

550KG |

|

Height offset |

60~110mm |

|

Manipulator |

|

|

Motor type |

JiaBao series |

|

Positioning repeatability |

0.001mm |

|

Axis working area(max) |

680mm*360mm*50mm |

|

Work station |

|

|

PCB fixation |

standard,specialization |

|

PCB loading/unloading |

manual |

|

PCB size (max) |

322mm*322mm |

|

PCB thick (max) |

5mm |

|

Fixturing |

|

|

Rigidity fixturing |

standard |

|

Fixturing fixation |

machinery |

|

Spindle Motor |

|

|

Power |

400W |

|

Spindle |

50000rpm/min |

|

Protect |

self/wind cooling |

|

Change cutter |

Specialization |

|

Routing capability |

|

|

Cutting speed(max.) |

100mm/s |

|

Driving speed(max.) |

3000mm/s |

|

Precision of cutting |

0.01mm |

|

Vacuum System |

|

|

Vacuum power |

2.2KW AC 380V |

|

Vacuum |

plumb |

|

Utilities |

|

|

Power |

2.2KW AC380V |

|

Air supply |

2~5KG/cm2 |

|

Programming |

|

|

Program edit |

Inline |

|

Function edit |

Line,arc,circula,U-curve |

|

Program storage |

HDD |

|

Vision system |

SONE colour CCD |

|

milling cutter offset |

AUTO |

|

Vacuum setup |

AUTO |

|

Operation Monitors |

|

|

Iindicator |

Iindicator Machine state |

|

tool check |

Automatic detection tool life, the use of time testing |

|

Motor protect |

Have overheating, overload, low voltage protection function |

|

motor over loading check |

Have Overload, the line is normal, low voltage protection function |

|

Tool usable time |

Automatic detection tool life, |

|

Data statistic |

Separate board model, separating count, diverse counting methods |

|

Error record |

Software automatically records all alarms memory of machines |

|

III. Accuracy |

|

|

Axis precision |

0.001mm |

|

Cutting precision |

0.1mm |

|

IV. Safety |

|

|

Working area protect |

With four sealed protection |

|

Door sensor |

Front and rear safety door micro-switch sensor (optional) |

|

Exigency stop button |

|

3.Function Description

1.X10 zoom-in image makes programming easier&increase the accuracy of point setting.

2.Two sliding table provides simultaneously in-and-out movement to reduce the tack time for better productivity.

3.AUTO MARK offset system.CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

4.routng bit automatically lift and shift to next programmed point then cutting to extend the life time of routing bit.

5. safety door industry design.

6. CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting.

PCB ROUTER铣刀分板机机械外观

随着电子工业的不断发展,电子产品重要组成部分基板的生产要求也越来越高,向高精度、高密度、高性能、小体积发展。为了适应市场要求,本公司长期市场调研综合世面上各品牌之优点,广泛听取用户各方面意见,制做出此款高速双模分板机JL-3500。

软件介绍:新一代识别系统

|

1:改变了传统的只能识别圆,方形等几何图型。可以识任何形状标识点。

2:不但具有纠错防呆功能,还可以较准数据,不用担心员工放错板。

3:位移功能,可以实现治具在工作台面任意摆放。 |

|

1:改变了传统的分段模式。

2:根据PCB的厚度来调整下刀深度,增加铣刀利用率,节省成本。

|

结构介绍

采用台湾45000转高速主轴24V高电压静电消除器断刀自动检测功能。采用WIN7系统操作介面,配置高像素彩色CCD放大10倍镜头,辅助程式示教及编辑模拟功能,精度更精确,图像更清晰。

PCB ROUTER铣刀分板机工作结构展示

|

软件介绍: |

双工作台设计 |

电控布局

|

X,Y切割速度 |

0~100mm/s |

|

机器重复精度 |

±0.02 |

|

分板尺寸 |

300mm*350mm |

|

X,Y1,Y2,Z控制方式 |

采用工业运动控制器+工业电脑 |

|

X,Y1,Y2,Z驱动方式 |

禾川伺服电达(可选配日本松下伺服电机) |

|

人机操作及资料储存 |

工业电脑 |

|

切割精度 |

±0.1 |

|

主轴转速 |

台湾主轴Max 45000rpm(可选配日本NSK或德国卡瓦) |

|

切割形式 |

直线、圆形、弧形、U型、L型等 |

|

影像 |

智能工业CCD |

|

操作介面 |

中/英双介面 |

|

Fidicuial Mark |

CCD自动对位功能 |

|

程式预览 |

CCD 路径模拟功能 |

|

主机电压 |

AC 220V 50/60Hz |

|

气压 |

5KG/CM² |

|

主机尺寸 |

1100 x 930 x 1700 (L X H X D)mm |

|

主机重量 |

600kg |

|

集尘方式 |

下集尘(可选下集尘) |

|

集尘器 |

3HP(可选 5HP) |

|

集尘机电源 |

AC 380V 50/60Hz |

|

集尘机尺寸 |

665 x 635 x 1610 (L X H X D)mm |

分板机主要配件

| 丝杆 | 台湾TBI丝杆 |

| 导轨 | 台湾MPI直线导轨 |

| 主轴 | 台湾主轴Max 45000rpm/四方变频器 (可选配日本NSK或德国卡瓦) |

| 伺服电机 | 禾川伺服电达 (可选配日本松下A6伺服电机) |

| 工控主机 | 工业计算机 |

| 显示器 | 飞利浦 LCD17" |

| CCD | 工业智能 CCD |

| 镜头 | 工业高清镜头 |

| 光源 | 工业调光器+50mmLED环型光源 |

| 电源 | 台湾明伟 |

| 继电器 | 欧姆龙继电器组 |